Freshly returned from the Mandelbrotian fractal shores of SIGGRAPH, my heart swells with 3D printing. Although primarily a computer graphics conference, all the major players in Additive Manufacturing were out in force: Stratasys, 3D Systems, and Formlabs (Thanks for the coupon code). Arguably, 3D printing isn't as much of a hot topic today as it was two or three years ago.

Why do you think that is?

Hypothesis: lack of hobbyist CAD users.

By now I'm sure you've heard my plastic Yoda head tirade. TL;DR - When given technology reminiscent of Star Trek replicators, why is it that most users produce junk inferior to that from a Mold-A-Rama?

Worthwhile CAD tools have traditionally been equal parts unaffordable and challenging to learn.

There was a time, not long ago, when you had to be a degreed professional, backed by a corporate bank account, to access CAD tools. Hell, it wasn't until the late 90's that desktop computers were fast, small, and economical enough to run CAD applications, which still to this day can cost thousands of dollars. One of the most widely-accepted CAD tool today, CATIA, isn't widely taught at the university level, despite having thousands of installations at major corporations like Boeing and GM.

Today is a totally different world. Off the top of my head I can think of a handful of very powerful CAD tools that are available to use for free, or nearly free. I grew up on Solidworks, so moving to Onshape was like moving from Coke to Diet Coke; the general flavor is similar, with less calories. Recently, I've spent an awful lot of time in Autodesk Fusion360 lately, and I must say, the more I use it, the more I like it. Where else can you find such powerful CAD/CAM tools that will take your shape and output code to your CNC machine? The price is definitely right, too.

For the more masochistic types out there, there's always Freecad (huh?), Sketchup (no thanks), and OpenSCAD (nope nope nope). Keep

in mind that 3D software breeds cliques that put teenage girls to

shame. Alls I'm saying is that there are options nowadays.

For the more masochistic types out there, there's always Freecad (huh?), Sketchup (no thanks), and OpenSCAD (nope nope nope). Keep

in mind that 3D software breeds cliques that put teenage girls to

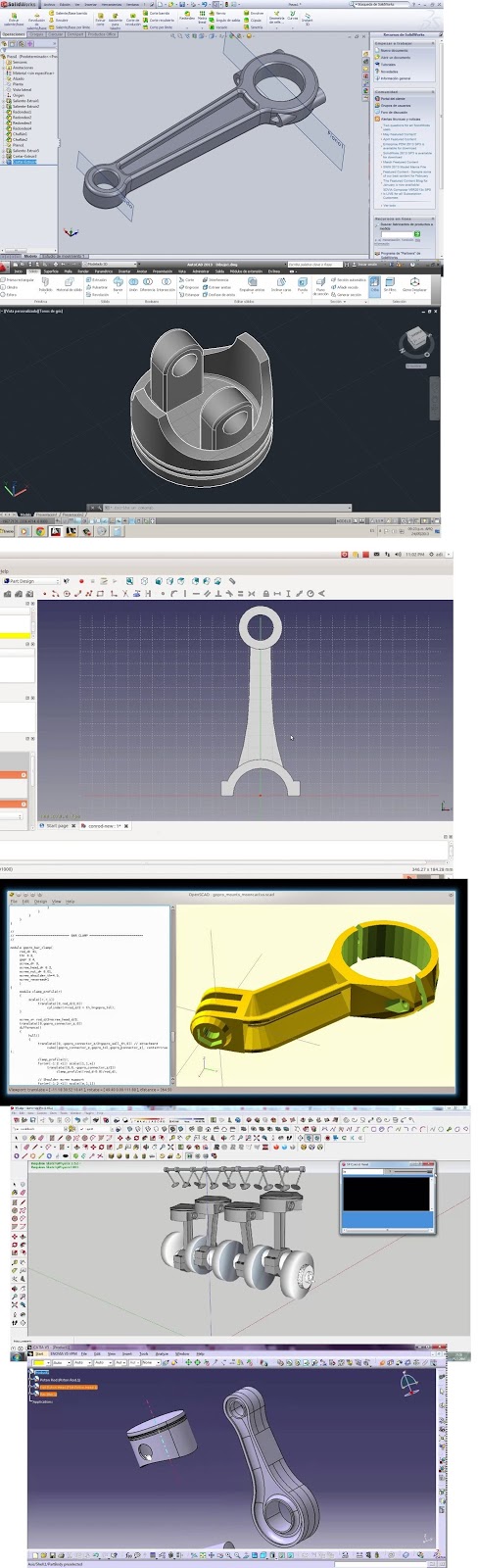

shame. Alls I'm saying is that there are options nowadays.On the left, you see the same basic design replicated in many different CAD environments. From the top, you have: Solidworks, Autocad Inventor, Freecad, OpenSCAD, Sketchup, and Catia. That's only naming a few of the choices out there.

They all will make the same part, the difference is in approach. Every single one of these softwares will output the fabled STL file, universally accepted by 3D printers everywhere*.

So far we've only covered CAD tools for engineering-type modeling. We haven't begun to explore the world of Direct Editing. Instead of designing parts in terms of dimensions and absolute shapes, Direct Editing, also known as Subdivision Modeling, is more like sculpting a statue out of clay. I don't have any personal experience with any of those yet, I'll get back to you when I do. To rattle off a few names: Maya, Zbrush, Blender, Rhino.....

Wise grandfather say - "The best time to plant a tree was twenty years ago. The second-best time to plant a tree is now." Whether you cut your teeth on Autocad '88 or have never touched CAD tools before, today's availability and accessibility of such tools is unprecedented. It certainly won't be a burden to your life to have a smattering of CAD, I promise.

Imagine what tomorrow can bring, considering that software development isn't going backwards any time soon.

WOW, it's looking marvelous. I really wanna do something like that.3D model can be printed with 3D printer. These tools are developing so fast and providing crazy ideas. It also used in constructed site. Try us to get professional helps.

ReplyDeleteawesome site

ReplyDelete3D Printer Service in Bengaluru

3d scanner

best 3d pen